Distillery Chillers

Whaley Products provides form-fitting distillery cooling solutions for beverage industry clients globally. Obtaining an extensive background in beverage industry process heat load analysis through years of experience has led to WPI’s processes of sizing, quoting, manufacturing, shipping, and servicing our clients’ distillery chiller systems a very calculated, strategic process. WPI provides air cooled chillers, water cooled chillers, pump tank systems, heat recovery systems, tank temperature control systems, control panels, and other products for the distillery industry.

Application Description:

Distillation is the process of separating liquid substances by evaporation and condensation. The distillation of fermented liquid products creates high alcohol content beverages for the beverage industry. The process of distillation in the beverage industry is wide-spread across many distilleries throughout the United States and worldwide. During the fermentation stage of the process, heat is created, and a glycol chiller system is necessary to circulate the distillation tanks and stills to remove the heat. Process heat exchangers are commonly used to provide an additional barrier between the customer’s product, and the food-grade propylene glycol.

Distillery Process Information:

Types of Distilled Liquors/Spirits

Distillery Calculations

Distillery Industry Links

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

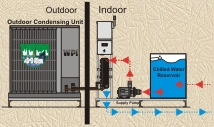

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |